CHEMICAL SURFACE TREATMENT

When you visit us you'll be struck by the craftsmanship that is still behind many high tech products. Over the years of collaboration with SAAB we have built up a specialised skill set in masking and surface treating aluminium alloys in small series production runs.

The work is performed in accordance with the strict specifications required by the defence industry.

Our surface treatment is performed entirely manually. Being meticulous and working within millimeter precision when masking and treating is more important to us than quantity. Your contact in Alumbra will handle the entire job including inspection and packing of each part.

We can undertake masking as well as anodising and chromating of aluminium components. We also undertake passivation of stainless steel.

Chemical Surface Treatment of Aluminium,

with chromium 6 and chromium 3.

We follow the REACH-directives Annex XIV when it comes to chromium 6 and continue to offer this service.

We also offer the alternative SurTec 650, based on chromium 3.

These processes meet the following standards :

• MIL-C-5541 Type I and II, Class 1A and 3

• SS-ISO 10546 Class 2 and 3

• EN 12487 Class C1 and A

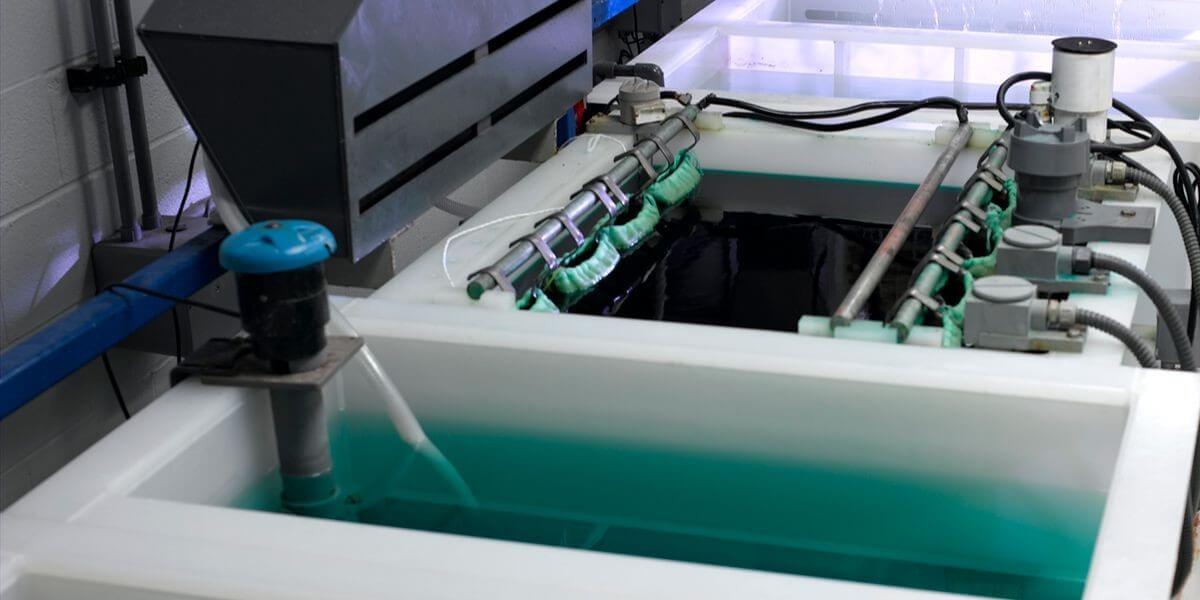

The chemical bath dimensions are 1200mmx600mmx600mm LxWxH.

Sulfuric Acid Anodizing,

clear and black.

In compliance with SS-ISO 8078, SS-ISO 8079, SS-ISO 7599.

The chemical bath volume is roughly 800 litres. The work space is approx. 1500mmx600mmx400mm LxWxH.

Stainless Steel Passivation

The bath dimensions and work space are 600mmx500mmx400mm LxWxH.